INDUSTRY 4.0 – DIGITAL TRANSFORMATION IN PHS PRODUCTION

SOMETIMES IT IS BETTER TO RELINQUISH CONTROL

The complexity of modern press hardening systems paired with the functional complexity of the products manufactured using this technology can hardly be controlled without sufficiently “intelligent” processing technology. This intelligence not only refers to aspects of process monitoring and storing process data, but, instead, it also refers to the autonomous definition and monitoring of process sequences in real time.

METAKUS possesses a database and base of knowledge that have grown over several decades, both of which make it possible to organize all complex interactions throughout the entire integrated processing chain of press hardening efficiently.

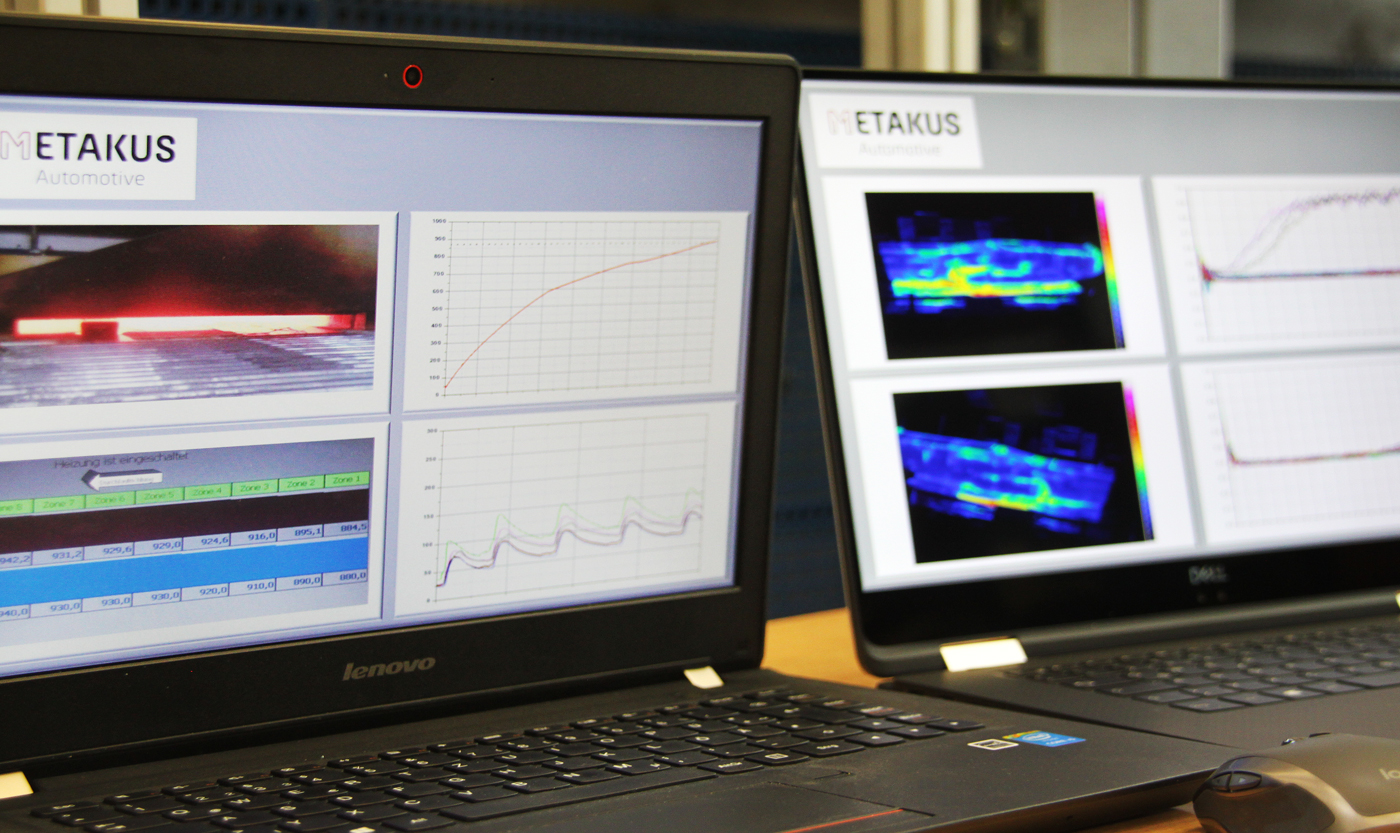

A one-of-a-kind real-time process control system, which is embedded in an intelligent digitally networked system environment and complemented by self-learning algorithms, is available for industrial manufacture of modern, press-hardened structural components intended for automotive construction.